You’ve all heard of the worldwide chip shortage by now. Inventories are low, and prices are a bit higher than usual. We know you have questions: “What are these ‘chips?’” “Why do we need them?” “Will this shortage ever end?” Here’s what you need to know.

What are semiconductor chips and why do we need them?

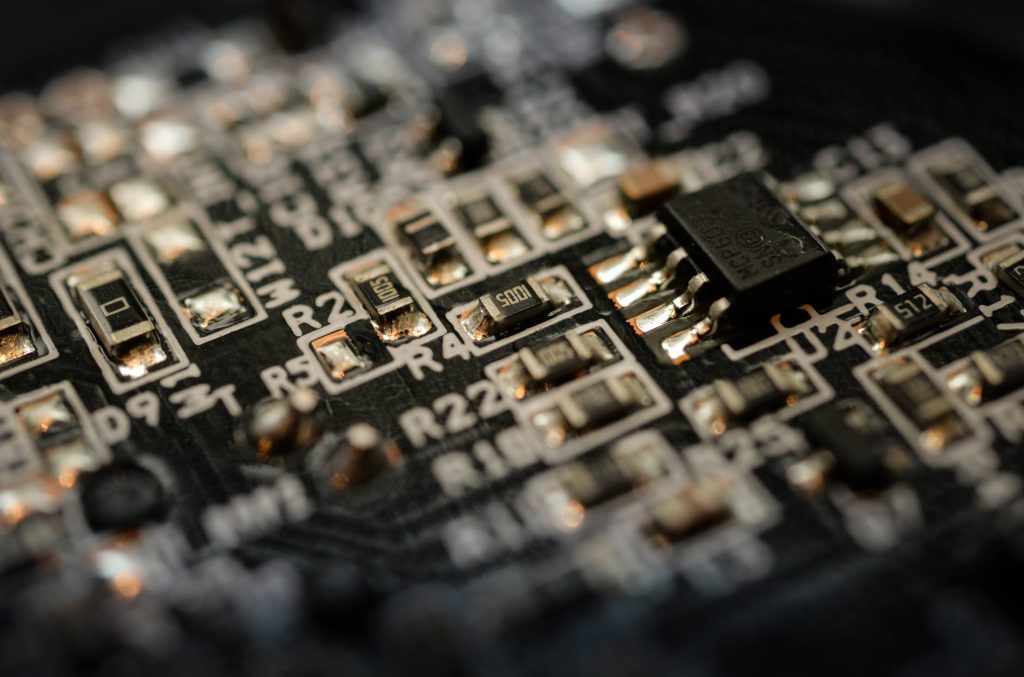

Semiconductor chips are complex. They are “groups of circuits that run software, manipulate data, and control the functions of electronic devices. The arrangement of those circuits gives each chip its specific purpose,” an article from Bloomberg reads. They are not interchangeable between devices, like a phone and a car, for example. Our vehicles require chips for all their incredible technology features, such as safety and suspension systems, engine and transmission operations, touchscreens, key fobs – the list goes on.

Simpler vehicles will have a lesser amount of chips, while newer vehicles can have thousands. CNBC explains how a Ford Focus uses around 300 chips, whereas one of their electric vehicles can have up to 3,000. With the popularity of electric vehicles rising, and ever-advanced safety technology, the demand for semiconductor chips is much higher than the supply can handle.

Unsurprisingly, semiconductor chips are not easy to make. According to Bloomberg, “Manufacturing a chip typically takes more than three months and involves giant factories, dust-free rooms, multi-million-dollar machines, molten tin, and lasers.” These facilities take years to construct and cost billions of dollars. A market forecast by World Semiconductor Trade Statistics reveals that semiconductor chip sales increased by 6.8% in 2020 to $440 billion. In 2021, they expect sales to rise 19.7% to $527 billion, and in 2022, 8.8% to $573 billion. If the industry is growing this quickly, why is there a shortage?

How did this happen?

In short, COVID-19 is primarily to blame. During the early stages of the pandemic, people were forced to work and learn from home, causing the demand for personal electronics to skyrocket. 5G phones alone require a lot more computer chips than older models. Initially, this wasn’t a problem because car manufacturers were freeing up part of the supply. They were canceling orders due to shutdowns and anticipation of plummeting auto sales. We did not expect how quickly the demand for vehicles would rebound.

With zero-percent financing offers and the bettered ability for customers to shop at home, there was an incredible demand once the factories reopened. By canceling previous orders, car manufacturers were left at the back of the line for their needed chips. In addition, the supply chain is physically struggling to meet demand as many products are stuck on container ships, waiting long periods to be unloaded and transported. Labor shortages are further hindering the situation.

Other unforeseen factors have affected manufacturing, such as a drought in Taiwan and a factory fire in Japan. Cryptocurrency’s appetite for chips has also put pressure on the issue, as well as the US-China trade war. This tension caused companies in China to stockpile semiconductor chips, inflating prices even further. Domestic chip production has been a national priority for China since 2014, according to John VerWey’s paper: “Chinese Semiconductor Industrial Policy: Past and Present.” Many chipmaking companies existed in the United States, but most have shut down or outsourced to other firms, mainly in Asia.

Who is it affecting?

Clearly, the global chip shortage is affecting parties all up and down the chain. It’s causing pain to sub-suppliers (e.g., tire companies), sales, jobs, future production — the economy in general. Consumers are facing limited options for used vehicles or extended wait times on new vehicle orders. Car dealerships are stuck with empty lots. Thousands of newly assembled vehicles are sitting, waiting on chips in order to be shipped out. Some companies have cut back on production, prioritizing select models. Others are shipping vehicles out without certain features, such as wireless charging or start/stop technology. Ford Motor Company views the shortage as a learning experience and is looking toward a bright future. The Drive spoke with Ford CEO Jim Farley, who claims Ford has seen improvement since the second quarter. Furthermore, they have been preparing for other potential shortages, creating their own stockpiles of materials.

When will the chip shortage end?

Sadly, there is no definite answer. Existing chip factories are working around the clock, but it may take a while for new manufacturers to get up and running. The U.S. is pushing to facilitate production and development domestically, allocating tens of billions of dollars toward the cause, an article from the Washington Post explains. In its entirety, the situation is slowly getting better. However, it could take into 2022 or even 2023 to return to some sort of normalcy. Only time will tell.

White’s Canyon Ford is continuing to mitigate the situation by remaining patient and focusing on customer satisfaction. We understand the frustrations anyone in the market may have, and we’re always ready to help. If you want to take advantage of the current used car market, give us a call. We offer on-the-spot appraisals and immediate purchases – any make or model.